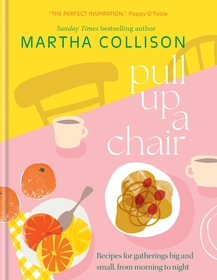

Managed Pressure Drilling: Fundamentals, Methods and Applications

Series: Gulf Drilling Guides;

- Publisher's listprice EUR 175.00

-

74 235 Ft (70 700 Ft + 5% VAT)

The price is estimated because at the time of ordering we do not know what conversion rates will apply to HUF / product currency when the book arrives. In case HUF is weaker, the price increases slightly, in case HUF is stronger, the price goes lower slightly.

- Discount 10% (cc. 7 424 Ft off)

- Discounted price 66 812 Ft (63 630 Ft + 5% VAT)

74 235 Ft

Availability

Not yet published.

Why don't you give exact delivery time?

Delivery time is estimated on our previous experiences. We give estimations only, because we order from outside Hungary, and the delivery time mainly depends on how quickly the publisher supplies the book. Faster or slower deliveries both happen, but we do our best to supply as quickly as possible.

Product details:

- Publisher Elsevier

- Date of Publication 16 May 2025

- ISBN 9780323916493

- Binding Paperback

- No. of pages440 pages

- Size 235x191 mm

- Weight 450 g

- Language English 700

Categories

Long description:

Managed Pressure Drilling Fundamentals, Methods and Applications, First Edition provides the basic infrastructure and extended support necessary for drilling engineers to apply managed pressure drilling to their operations. Enhanced with multiple new chapters and contributions from both academic and corporate authors, this reference provides engineers with the basic processes and equipment behind MPD. Other sections explain the latest technology and real-world case studies, such as how to optimize the managed pressure drilling system, how to choose the best well candidate for MPD, and how to lower costs for land-based operations. Packed with a glossary, list of standards, and a well classification system, this book is a flagship reference for drilling engineers on how to understand basics and advances in this fast-paced area of oil and gas technology.

- Demonstrates the value in safety improvement, time and cost savings, sustainability and reduced carbon footprint that adoption of MPD brings to well construction.

- Delivers a fundamental collection on managed pressure drilling equipment, methods, procedures, best practices, and field cases.?

- Presents a balance of information that ranges from historical details and background theory to practical application

- Includes multiple critical chapters dealing with all major MPD variants, MPD event detection, control systems and automation, how to plan and risk MPD, where MPD fits in the well delivery process, and its future outlook.

Table of Contents:

Preface

A Note on Notation

Chapter 1 - Introduction

1.1. What is MPD?

1.2. MPD Variants, Terminology & Classification

1.3. Brief History and Overview of MPD Variants

1.3.1. General Introduction

1.3.2. Continuous Circulation

1.3.3. Surface Back Pressure MPD

1.3.4. Riserless and Dual-Gradient Drilling

1.3.5. Mud Cap Drilling

1.3.6. Managed Pressure Cementing and Completions

1.4. Main Benefits & Advantages of MPD

1.5. The Stakeholder Case for Action - Why Adopt MPD?

2. Fundamentals & Essential Background

2.1. Introduction

2.2. Hydraulics

2.2.1. Hydraulics Introduction

2.2.2. Hydrostatics

2.2.2.1. Definitions

2.2.2.2. Density - Ideal and Non-Ideal Mixing

2.2.2.3. Incompressible Fluids

2.2.2.4. Compressible Fluids

2.2.2.5. Effect of Hole Cleaning and Barite Sag on Density

2.2.2.6. Multiple Fluid Gradients & Unbalanced U-Tube Effects

2.2.3. Hydrodynamics

2.2.3.1. Pump Pressure, Frictional Pressure Loss & ECD

2.2.3.2. Hydraulics Models

2.2.3.3. Hydraulic Modeling: Calculating Frictional Pressure Losses during Circulation

2.2.3.4. Transient Effects: Surge & Swab

2.2.3.5. Transient Effects: Mud Gelation and Pump Startups

2.2.3.6. Hole Cleaning

2.2.3.7. Bit Pressure Drop

2.2.3.8. Other Hydraulic Pressure Losses

2.2.3.9. Uncertainty in Hydraulic Modeling

2.3. Rock Mechanics and the Drilling Margin

2.3.1. Drilling Margin Introduction

2.3.2. Pore Pressure

2.3.2.1. Pore Pressure Introduction

2.3.2.2. Pore Pressure Regimes

2.3.2.3. Deepwater Pore Pressure - Effect of Water Depth

2.3.2.4. Pore Pressure Indicators

2.3.2.5. Pore Pressure Evaluation and Prediction

2.3.3. Fracture Gradient

2.3.3.1 Fracture Gradient Introduction

2.3.3.2. Formation Integrity & Leak-Off Testing, Dynamic MPD Testing

2.3.3.3. Fracture Gradient Considerations

2.3.3.4. Ballooning / Losses & Gains / Wellbore Breathing

2.3.3.5. Fracture Gradient Evaluation and Prediction

2.3.4. Effect of Depletion on Pore Pressure and Fracture Gradient

2.3.5. Borehole Stability

2.3.5.1. Borehole Stability Introduction

2.3.5.2. Stress Tensor & Subsurface Stress Regimes

2.3.5.3. Subsurface Stress and Rock Failure

2.3.5.4. Near-Wellbore Stresses & Failure Orientation

2.3.5.5. Mud Weight for Borehole Stability - Avoiding Shear Failure

2.3.5.6. Mud Weight to Prevent Tensile Failure & Induced Fracturing

2.3.5.7. Wellbore Trajectory and the Drilling Margin

2.3.5.8. Obtaining Borehole Stability Modeling Input Variables

2.3.5.9. Borehole Stability Modeling Recommendations

2.3.6. Extending the Drilling Margin: Artificial Wellbore Strengthening

2.4. Well Control

2.4.1. Well Control Introduction

2.4.2. Definitions

2.4.3. Conventional Kick Detection

2.4.4. Wellbore Breathing Detection & Flowback Fingerprinting

2.4.5. Conventional Well Shut-In, SIDPP & SICP

2.4.6. MAASP/MASP & MAWP

2.4.7. Kick Intensity (KI) & Kick Tolerance (KT)

2.4.8. Casing Point Selection

2.4.9. Phase-Behavior of Gases

2.4.10. Gas Solubility

2.4.11. Conventional Well Control Methods

2.4.11.1. Driller’s Method

2.4.11.2. Wait & Weight Method

2.4.11.3. Bullheading / Annular Injection

2.4.11.4. Subsea Well Control

2.4.11.5. Riser Margin and Emergency Riser Disconnects

2.4.12. Mud Gas Separator (MGS) Sizing

2.4.12.1. Gas Separation Capacity

2.4.12.2. Maximum Allowable Internal Pressure and Gas Flow Rate

2.5. Speed of Sound

2.6. Temperature Effects

2.6.1. Introduction

2.6.2. Temperature Regimes, HPHT Classification

2.6.3. Temperature Modeling

2.6.4. Effect of Temperature on Fluid Properties

2.6.5. Effect of Temperature on Wellbore Stability and Lost Circulation

2.6.6. Effect of Temperature on MAASP and Kick Tolerance

2.6.7. Effect of Temperature during Non-Circulatory Periods / Connections

2.7. Pipe Light Conditions

2.8. Recommended Reading

3. MPD Benefits and Risks

3.1. Introduction - How MPD Changes the Game and Adds Value

3.2. Improved Safety

3.2.1. Early Kick Detection (EKD), Early Kick & Loss Detection (EKLD)

3.2.2. Improved Pressure Control and Influx Management

3.2.3. Dynamic Pore Pressure, Formation Integrity and Leak Off Testing (DPPT, DFIT, DLOT)

3.3. Well Design Optimization

3.4. NPT Avoidance

3.4.1. Lost Circulation and Wellbore Breathing Prevention and Mitigation

3.4.2. Wellbore Instability and Stuck Pipe Prevention

3.4.3. Differential Sticking and Stuck Pipe Prevention

3.4.4. Remedial Cementing Avoidance through Managed Pressure Cementing

3.4.5. Optimized Completions

3.5. Invisible Lost Time (ILT) Avoidance & ROP Enhancement

3.6. Reduced Reservoir Damage and Production Optimization

3.7. Reduced Carbon Footprint of Well Construction Operations

3.9. Risks and Drawbacks of MPD

3.10. Techno-Economical Justification of MPD

4. MPD Equipment, Software and Operational Implementation

4.1. Introduction

4.2. MPD Equipment

4.2.1. Rotating / Non-Rotating Control Devices (RCD/ACD)

4.2.1.1. Passive RCD Systems

4.2.1.2. Active RCD Systems

4.2.1.3. Active Closing Device (ACD) Systems

4.2.1.4. Hybrid RCD Systems

4.2.1.5. Integrated Pressure Management Device (PMD)

4.2.1.6. RCD Sealing Element Life

4.2.2. Chokes & Choke Manifolds

4.2.3. Flow Metering

4.2.4. Non-Return Valves (NRV)

4.2.5. Pressure Relief Valves (PRV), Pressure Relief Chokes (PRC), Pressure Control Valves (PCV)

4.2.6. Junk / Debris Catchers

4.2.7. Distribution / Buffer Manifolds

4.2.8. Piping, Hoses and Flowlines

4.2.9. Special Downhole Valves

4.2.9.1. Casing Isolation Valve (CIV) / Downhole Isolation Valve (DIV)

4.2.9.2. Drill String Valve (DSV) / Hydrostatic Control Valve (HCV)

4.2.10. Back-Pressure Pumps

4.2.11. Mud Gas Separator (MGS)

4.2.12. Riser Equipment & Configurations, Integrated Riser Joint (IRJ)

4.2.13. Downhole Measurements & Telemetry

4.2.14. Programmable Logic Controllers

4.3. MPD Operational Implementation

4.3.1. Piping and Instrumentation Diagrams (P&ID), Process Flow Diagrams (PFD)

4.3.2. MPD Certification, Commissioning and Classification

4.3.3. MPD Fingerprinting

4.3.4. MPD Rig Integration

4.3.4.1. General Considerations

4.3.4.2. Land Rigs

4.3.4.2. Offshore Rigs - Jack-Ups & Platform Rigs

4.3.4.3. Offshore Rigs - Deepwater MODUs

4.3.5. Pressure Operations Directive

4.4. MPD Software and Data-Acquisition

4.5. Recommended Reading

5. Continuous Circulation (CC)

5.1. Introduction

5.2. Unique Systems, Equipment and Methods

5.2.1. Continuous Circulation System (CCS)

5.2.2. Continuous Circulation Valves (CCV)

5.2.2.1. Eni Circulation Device (e-cdTM)

5.2.2.2. Non-Stop Driller (NSDTM)

5.2.2.3. Continuous Flow System (CFSTM)

5.2.2.4. Rotating Continuous Circulation Tool (RCCT)

5.3. Kick Detection and Well Control

5.4. Tripping

5.5. Case Histories

5.5.1. CCS

5.5.2. CCV

5.6. Recommended Reading

6. Surface Back Pressure (SBP)

6.1. Introduction

6.2. Drilling Margin Management

6.2.1. Adding Back-Pressure to Control Annulus / Bottom-Hole Pressures

6.2.2. Anchor Point Selection & Management

6.2.3. Basis of Design (BOD)

6.2.4. Dynamic Pore Pressure, Formation Integrity and Leak Off Testing (DPPT, DFIT, DLOT) 404

6.2.5. Tripping, Compensating for Swab & Surge Pressures

6.2.6. Heave Compensation

6.3. Pressure Control & Influx Management

6.3.1. Introduction

6.3.2. Early Kick & Loss Detection (EKLD)

6.3.3. Influx Management

6.3.3.1. Primary & Secondary Barrier Operations

6.3.3.2. MPD Operations Matrix

6.3.3.3. MPD Influx Management Envelope (IME)

6.3.3.4. MPD Influx Management Decision Tree (IMDT)

6.3.4. SMAASP & DMAASP

6.3.5. Mud Weight and SBP Selection using SMAASP & DMAASP

6.3.6. Kick Tolerance and Well Design / Casing Point Optimization

6.3.7. Riser Gas Handling (RGH) to Prevent Riser Gas Unloading (RGU) Events

6.3.7.1. Introduction

6.3.7.2. RGH / RGU Experimentation, Riser Gas Migration Monitoring

6.3.7.3. RGH / RGU Modeling

6.3.7.4. Gas Hydrates

6.3.7.5. IADC Riser Gas Handling Guidelines

6.3.7.6. Riser Gas Handling Equipment

6.3.7.7. Influx Management Envelope (IME) for Riser Gas Handling Events

6.3.7.8. Handling Gas-in-Riser with Back-Pressure and Dilution Control

6.4. SBP Methods and Systems

6.4.1. Manual Approach with Trapped Back-Pressure

6.4.2. Automated Approach with Trapped Back-Pressure

6.4.3. Automated Approach with Added Back-Pressure

6.5. SBP-MPD for Challenging Wells

6.5.1. (Ultra-)Deepwater Wells

6.5.2. High Pressure High Temperature (HPHT) Wells

6.5.3. Extended Reach Drilling (ERD) Wells

6.6. SBP Case Histories

6.7. Recommended Reading

7. Dual Gradient Drilling (DGD)

7.1. General Introduction

7.2. Riserless Drilling (RD) - Weighted Mud Discharge at the Seafloor

7.2.1. RD Introduction

7.2.2. RD Systems, Equipment and Operation

7.2.3. RD Case Histories

Intermezzo - Road to RMR: Cuttings Transport System (CTS)

7.3. Riserless Mud Recovery (RMR)

7.3.1. RMR Introduction

7.3.2. RMR Systems and Equipment

7.3.3. RMR Operation

7.3.3. RMR Case Histories

Intermezzo - Road to CML

7.4. Controlled (Annular) Mud Level (CML / CAML)

7.4.1. CML Introduction

Intermezzo - ECD Management Toolbox

7.4.2. CML Systems, Equipment and Operation

7.4.3. CML Operation

7.4.4. CML Kick Detection & Well Control

7.4.4.1. CML Kick Detection

Intermezzo - CMP Well Control Trials Using the CML System

7.4.4.2. CML Well Control

7.4.5. CML+SBP

7.4.6. CML Case Histories

7.5. Inactive Systems

7.5.1. Seabed Pumping

7.5.1.1. Subsea Mudlift Drilling (SMD)

7.5.1.2. DeepVision

7.5.1.3. Shell Subsea Pumping System (SSPS)

7.5.2. Riser Dilution

7.5.2.1. Dilution with Gas

7.5.2.2. Dilution with Hollow Spheres - Maurer JIP

7.5.2.3. Dilution with Light Fluid - Continuous Annular Pressure Management (CAPM)

7.5.3. Mid-Level Riser Pumping

7.5.3.1. Low Riser Return System (LRRS)

7.5.3.2. DeltaVision / Pumped Riser System (PRS)

7.5.4. Miscellaneous DGD Methods

7.5.4.1. Dual Drillstring - Reelwell

7.5.4.2. E-duct Return (EdR)

7.6. Recommended Reading

8. Mud Cap Drilling (MCD)

8.1. Introduction

8.2. MCD Subvariants

8.2.1. Floating Mud Cap Drilling (FMCD)

8.2.2. Pressurized Mud Cap Drilling (PMCD)

8.2.3. Dynamic Mud Cap Drilling (DMCD)

8.2.4. Controlled Mud Cap Drilling (CMCD)

8.2.5. Variant Selection and Comparison: FMCD vs. PMCD

8.3. Gas Migration in MCD Operations

8.4. Planning and Executing PMCD Operations

8.4.1. Planning and Preparation

8.4.2. Equipment

8.4.3. Pit layout & fluid management

8.4.4. Transitioning between MCD and Conventional or SBP-MPD Operations

8.4.5. Well control

8.4.6. Drilling

8.4.7. Tripping

8.5. PMCD Wireline and Coring Operations

8.6. Case Histories

8.6.1. FMCD Field Cases

8.6.2. PMCD & DMCD Field Cases

8.7. Recommended Reading

9. Managed Pressure Cementing (MPC), Managed Pressure Completions (MPComp), Managed Pressure Casing/Liner/Completion Running

9.1. General Introduction

9.2. Managed Pressure Cementing (MPC)

9.2.1. MPC Introduction

9.2.2. MPC with SBP

9.2.2.1. Equipment

9.2.2.2. Workflow - Planning & Execution

9.2.2.3. Casing vs. Liner MPC Considerations

9.2.2.4. Risks

9.2.3. MPC with RMR & CML

9.2.4. MPC Modeling & Control

9.2.5. MPC Case Histories

9.3. Managed Pressure Completions (MPComp)

9.4. Downhole Measurements during MPC & MP Completions

9.5. Recommended Reading

10. Miscellaneous Methods: RMD, Multi-Phase MPD, Reelwell

10.1. Introduction

10.2. RMD / RCD-Only / HSE Method

10.3. Multi-Phase MPD

10.3.1. Equipment & Preparation

10.3.2. Modeling & Simulation

10.3.3. Direct Injection vs. Concentric Injection

10.3.4. Well Control, Connections and Tripping

10.3.5. Case Histories

10.4. Reelwell Pipe-in-Pipe Technology

10.5. Recommended Reading

11. MPD Event Detection, Automation and Control

11.1. General Introduction

11.2. Introduction to Drilling and MPD Automation

11.2.1. Drivers for Automation

11.2.2. Levels of Automation (LOA)

11.2.3. Current State of Drilling Automation & MPD Automation

11.2.3.1. Drilling Automation

11.2.3.2. MPD Automation

11.2.4. Human Factors (HF) & Situational Awareness (SA)

11.3. Event Detection

11.3.1. Artificial Intelligence (AI) and Machine Learning (ML) Introduction

11.3.2. AI & ML Methods Overview

11.3.3. Simple Rule-Based Event Detection

11.3.4. AI & ML-Based Event Detection

11.3.5. AI & ML-Based MPD Risk and Reliability Assessment

11.3.6. AI & ML-Based Advisory at the Rigsite

11.4. Automated MPD Control

11.4.1. Closed-Loop vs. Open-Loop Control

11.4.2. Process and Control Variables, Disturbances

11.4.3. Manual and Automated Control

11.4.3.1. Manual Control

11.4.3.2. Two-Position On/Off Control

11.4.3.3. Proportional (P), Integral (I) and Derivative (D) Control

11.4.3.4. Model-Predictive Control (MPC)

11.4.3.5. Other Control Approaches

11.4.4. Models for Estimation and Control

11.4.4.1. Introduction

11.4.4.2. Simple ODE Control Approach

11.4.4.3. RDFM Control Approach

11.4.4.4. Control Switching: Pressure, Flow and Solubility Control

11.4.5. Automated Tripping Advisory and Control

11.4.6. Automated Heave Control

11.4.7. Automated Fluid Monitoring

11.4.8. Automated Well Control

11.5. Digital Twinning & Hybrid Modeling

11.5.1. Digital Twinning

11.5.2. Hybrid Modeling: Combining Physics-Based and Data-Driven Modeling

11.6. Recommended Reading

12. MPD Planning, Implementation and Risk Management

12.1. Well Construction Process (WCP)

12.1.1. WCP Phases and Structure

12.1.2. WCP Risk Register

12.1.3. WCP Roles and Responsibilities

12.1.4. WCP Value Creation, Erosion or Missed Opportunity

12.1.5. WCP Cost Estimating

12.1.6. WCP Key Performance Indicators (KPIs) & Benchmarking

12.1.6.1. Safety

12.1.6.2. Drilling Time & Cost

12.1.6.3. Trouble and Inefficiency Time and Cost: NPT & ILT

12.1.6.4. Production Added

12.1.6.5. Sustainability Indicators

12.1.6.6. Staffing

12.1.6.7. Performance Benchmarking

12.2. MPD Project Management

12.2.1. Introduction.

12.2.2. Project Scoping

12.2.2.1. MPD Candidate Selection

12.2.2.2. Technical Feasibility

12.2.2.3. Economic Feasibility

12.2.3. Front End Engineering & Design (FEED)

12.2.4. Implementation

12.2.7.3. Knowledge Management: After Action Review (AAR)

12.2.7.4. Management of Change (MOC)

12.3. MPD Risk Assessment

12.3.1. Introduction

12.3.2. IADC Well Classification System

12.3.3. HAZID/HAZOP

12.3.4. FMEA/FMECA

12.3.5. LOPA/SIL

12.3.6. HSE Risk Matrix

12.3.7. HSE Risk Register

12.3.7. Cause and Effect Diagram and Table

12.3.8. Bow-Tie Analysis and Diagrams

12.3.9. Fault Tree Analysis (FTA)

12.3.10 Event Tree Analysis (ETA)

12.3.11 Linkage between Risk Assessment Approaches and HSE Management System

12.4. Training & Competency Assessment

12.5. Regulatory Approval

12.6. Summary: Key Documents, Events and Success Measures

12.7. Recommended Reading

13. Future Outlook

13.1. Introduction - MPD Projected Growth

13.2. Talent Attraction, Retention & Training

13.3. Technology Maturation & Continuous Improvement

13.4. Collaborative Regulatory Environment

13.5. Managed Pressure Engineering (MPE)

13.6. Rig Integration and Standardization

13.7. Riser Gas Handling & Riser Well Control

13.8. Automation, Data-Analysis, ML & AI, Digital Twinning, Hybrid Models, Remote Operations

13.9. Data Sharing and Collaboration

13.10. Environmental Benefits

13.11. Future Applications

13.12. Conclusion

Appendix A - Drift Flux Model (DFM) and Reduced Drift Flux Model (RDFM)

A.1. DFM Formulation

A.2. RDFM Formulation

A.3. Numerical Simulation

Appendix B - Hydraulics & Hole Cleaning Addendum

B.1 Estimation of Pressure Losses in Annuli using the Finite Difference Method

B.2. Modeling Thixotropic Fluid Behavior and Estimating Pressure Transients During Flow Initiation

B.3. Modeling Cuttings Transport using Local Fluid Velocities

B.3.1. Calculation of Velocity Profile in the Annulus using the Narrow Slot Approximation

B.3.2. Calculation of Local Critical Velocity

Appendix C - Rock Mechanics Addendum

C.1. Modified Lade, Modified Wiebols-Cook and Mogi-Coulomb Criteria

C.2. Physico-Chemical Effects on Wellbore Stability

C.3. Rock Strength Anisotropy Effects

Appendix D - Kick Tolerance Calculations

D.1. KT Formula Derivation - Conventional Drilling

D.2. KT Formula Derivation - SBP-MPD

Appendix E - Gas Solubility Example

List of Acronyms

Nomenclature

Variables

Greek letters

Subscripts & Superscripts

References